News

As a professional heat treatment of heat-resistant steel tooling equipment manufacturers, based on years of experience, or give some advice to the user. After the master, to improve the life of heat-resistant steel castings, reduce production costs, etc. are of great benefit.

A recommendation, carburizing furnace and its accessories before use to conduct a tempering and temperature control as well as the holding time should meet the requirements, the purpose is to eliminate the internal stress of the casting process.

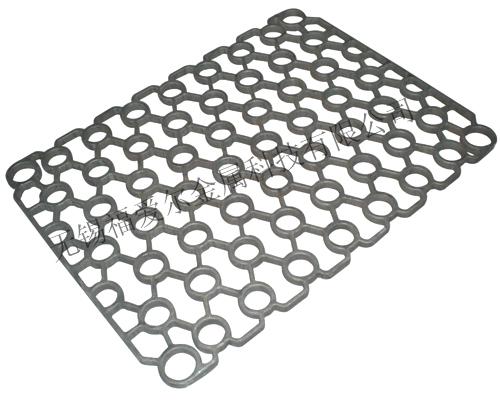

Recommendation II, stove plate during use, we must ensure that the workpiece placed evenly, you can not work in one local stacking position, this would lead to uneven heat oven plate during the heating process, the furnace is likely to cause deformation of the plate and cracking, to prevent oxidation of skin breakdown caused by short circuit resistance wire furnace floor.

Recommendation III, spreader used during the casting process, the basket must be careful selection, the best choice of material for ZG40Gr25Ni20 electrode, it is because of good performance in creep hardening process will not cause the spreader and pockets of serious deformation and cracking.